Shot blasting on products deriving directly from iron and steel industry is aimed at eliminating burrs, oxides and welding scale on roller benches. This processing is necessary to obtain products suitable for further processing or painting.

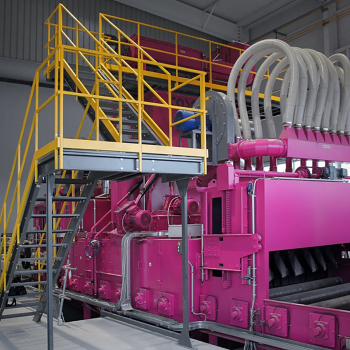

The surface cleaning of metal sheets, section bars and profiles is possible thanks to continuous tunnel systems in which materials are generally moved through belt conveyors with rollers. The control unit makes it possible to adjust passage speed, which is set according to the initial state of the surfaces to treat and the desired degree of finishing.

The turbines, which are strategically positioned above and below the slide bed conveyors, guarantee perfect cleaning of the surfaces to pickle in one single pass.