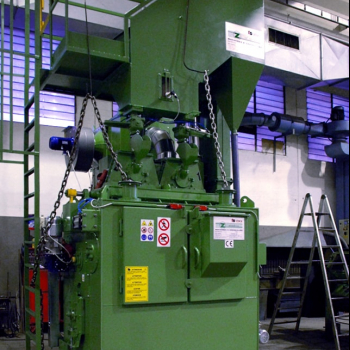

Hot-press forged products often present burrs, ridges and pigmentation, which must necessarily be eliminated through shot blasting before further processing.

Shot blasting is carried out with intermittent loads through a metal or rubber feeding belt, or continuously using air or belt conveyors.